Refrigerated truck bodies

Within the truck body market we have specialised in constructing refrigerated truck bodies (also known as conditioned truck bodies). We use truck bodies of our partner Isobox Srl, which can be used for both heated and refrigerated transport.

Excellent temperature control

A truck body is generally used in a company specific way, after all every cargo is unique. EBO van Weel closely involves its customers in the design process of the truck body.

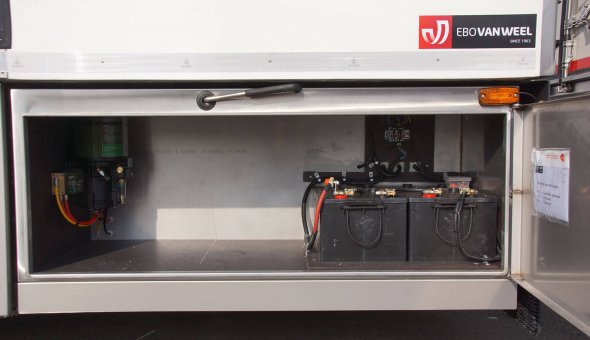

For heating, cooling and freezing installations a fitting scheme is developed, adapted to the cargoes being transported. Its reliability is not only important for the preservability of your cargo, but also for the energy consumption of your truck body. Thanks to the use of the right combination of parts, fuel costs can be saved.

We can install heaters and coolers of all brands Furthermore we can advise you about the air distribution.

We can install heaters and coolers of all brands Furthermore we can advise you about the air distribution.

Compartments for varying cargoes

To make everything fitting to your transport needs, we can arrange the superstructure with compartments and double floors for you. Also, multi-temperature cooling can be chosen as an option. To enhance the functionality of the superstructure, side doors can be included at any desired position. Your wish is our mission!

A beneficial durability

High-quality parts are used for the floor, to ensure a strong construction for a long time. This make it possible to use wheeled containers with high point loading intensively and for a long time without problems.

Pallet trucks and trolleys are mainly used by customers from distribution and refrigerated transport. This is one of the most intense loads for a floor to endure. Because of the quality of our products we can ensure you that you won’t experience any problems.

You can contact our regular customers as a reference.

Wet-in-wet production process

We construct our fridge-freezer bodywork with insulated superstructures of Isobox Srl. The production of the fridge-freezer superstructure is characterised by the ‘wet-in-wet’ procedure. CFC-free foam cores are ‘wet-in-wet’ connected to a polyester inner and outer layer. This creates a homogeneous bodywork structure, which is unyielding and 100% waterproof. There is no need for sealants.

Furthermore, the foam consists of closed cells, so that the foam doesn’t absorb water when damaged. This can save a lot of costs, since moisture can cause a lot of damage.

Here you see a snapshot of the layering: the glue is dispensed after which the foam will be applied.

Here you see a snapshot of the layering: the glue is dispensed after which the foam will be applied.

You are represented with a smooth design

The Isobox Srl truck bodies are characterised by the absence of corner frames and the imperceptibility of the internal reinforcements of the panels. Combined with qualitative spraying, this creates a smooth design.

Furthermore the bodywork is constructed with high-quality assembly parts, which shows we care about every optical detail of your refrigerated truck body, e.g. stainless steel door and window fittings, spoilers and different types of lighting.

Our collaboration with Isobox Srl

Since April 2013, EBO van Weel has taken controlling interest in Isobox Srl, an Italian polyester bodywork manufacturer. Thanks to this collaboration EBO van Weel can develop itself in the production of refrigerated truck bodies and repositions itself in the conglomerate of bodywork manufacturers.

In addition, our product quality can be better guaranteed and customisation is easier to apply. Due to this collaboration we can process our customer specific requests in a better way.

We have a trouble-free collaboration with Isobox Srl thanks to our controlling interest.

We have a trouble-free collaboration with Isobox Srl thanks to our controlling interest.